MSc Mechanical Engineering

Advanced Manufacturing (M-ENG AM)

- Programme Objectives

-

This specialism in Mechanical Engineering develops skills for providing innovative and optimized solutions in the advanced design and manufacturing of products and structures for both research and industry.

The courses rely on both theoretical and practical aspects and cover the following areas: mechanical design of innovative mechanisms and products and customer-oriented design of products. Technical, human and economic factors are taken into account.

The programme of study lasts two academic years - denoted by M1 and M2 and is taught in English. It comprises three study semesters followed by a paid Master's thesis / internship in the final semester.

Our Master's programmes in Mechanical Engineering are fully accredited by the French Ministry of Higher Education and Research.Contribution to sustainable development goals

► Learn more about Centrale Nantes' commitment to the 17 sustainable development goalsWatch the Campus Channel Replay:

- Course Content

-

30 ECTS Credits per semester.

Language of instruction: English

- M1 Year - 2023/24

-

Autumn Semester Courses ECTS Spring Semester Courses ECTS Continuum Mechanics 5 Engineering Materials 5 Fluid Mechanics 5 Constitutive Laws 5 Algorithmics for Engineering Modelling 4 Structural Mechanics 5 Numerical Methods 5 Computer-aided Design 5 Vibrations and Differential Equations 5 Mechanical Design 5 Business Environment 4 Conferences and Initiation to Research 3 Modern Languages * 2 Modern Languages * 2 Conferences 0

* 'French as Foreign Language' except for French native speakers who will study 'Cultural and Communicational English' or Spanish (depending on sufficient demand).

NB Course content may be subject to minor changes - M2 Year - 2023/24

-

Autumn Semester Courses ECTS Advanced CAD/CAM/CNC 5 Additive Manufacturing and advanced manufacturing processes 5 Design of Experiments methods for manufacturing 5 Optimization in manufacturing engineering 5 Integrated Design of Product Service Systems 4 Multi-physics modelling for processes 4 Modern Languages * 2 Conferences -

* 'French as Foreign Language' except for French native speakers who will study 'Cultural and Communicational English' or Spanish (depending on sufficient demand).

NB Course content may be subject to minor changes

Spring Semester ECTS Master thesis / internship 30 Examples of previous Master theses/internships

- Ikerlan - Design, optimisation and experimental validation of a high-speed mechanism

- EPFL - Study of the thermomechanical transformations for different metal alloys, produced by LPBF and research into suitable thermal processes

- Vallourec - Development of a multidisciplinary design tool for Design Selection phases

- GE WIND France SAS - Development and improvement of the current design of bolted connections within the offshore wind turbine

- Technip Energies France - Process definition and development of an automated welding machine for the assembly of the floating wind turbine components

- Timken Europe - Development of model of bearing creep phenomenon

- Faurecia Interior Industries - Assistant plastic injection engineer

- SNCF - Additive Manufacturing Design and Simulation Engineer

NB Internships undertaken in France are strictly regulated and are only open to current full-time students of an accredited educational institution. Interns are entitled to all the rights guaranteed to regular employees (such as social protection and redress mechanisms). For internships that exceed two months in duration a minimum level of remuneration is set by the government, at approximately €600 per month. In some professional branches, this amount may be higher. - Skills developed

-

- Develop innovative processes and products for composite and metallic materials and structures

- Design products adapted to the processes

- Work in an integrated numerical environment and in a design & manufacturing global chain

In addition to the above specialism-specific skills, students will also develop more general skills:

- Identify models, perform simulation and analyse results

- Communicate comprehensive results in a meaningful way

- Undertake bibliographic surveys of international research and professional literature

- Manage or be part of a project

Download syllabus | Mechanical Engineering - Advanced Manufacturing

- Facilities and Partnerships

-

Faculty and Research Facilities

This Mechanical Engineering programme relies on Centrale Nantes’ faculty and the research facilities of the GeM and the LS2N.Focus on unique resources

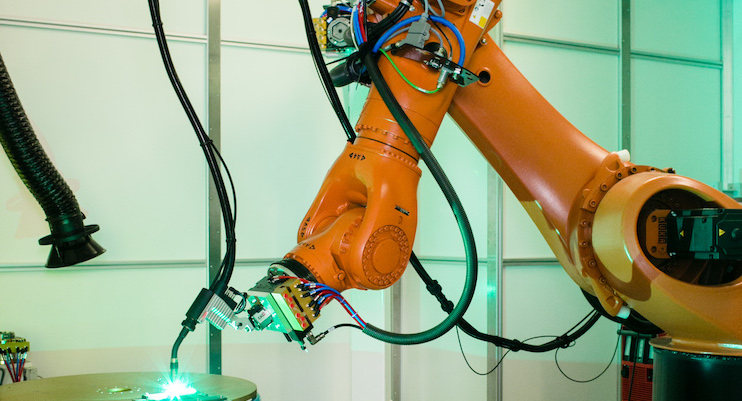

Smart Factory Platform

"This smart platform offers everything that we could expect from a production system: it is modular, reconfigurable, agile and flexible. It demonstrates the modern concepts of the industry of the future, integrating diversity management, total production traceability and detailed quality monitoring". - Emeritus Professor Alain BernardPartnerships

Naval Group, Airbus, Chantier de l'Atlantique, General Electric, Renault, PSA

- Admissions

-

- Apply online on the eCandidat platform

- 2024/25 intake: applications open on 30 October 2023

- Application process

-

Application rounds

- Applications are reviewed in rounds. M1 applicants may apply in any of the three M1 rounds, and M2 applicants in either of the two M2 rounds. Applications should be submitted on the eCandidat platform as early as possible, but before the deadlines below;

- Applications are not considered 'complete' until all required elements are submitted. Only complete applications received by the round's deadline will be considered in that round;

- The admissions board reviews applications at the conclusion of each round and notifies each applicant of the outcome of their application;

Accepting your place

- Successful applicants must accept their place on the eCandidat platform by the deadlines below;

- The first installment of tuition fees must be paid by the deadlines below to definitively secure the applicant's place on the programme.

Deadlines for the 2024-25 intake

M1 | Round 1 M1 | Round 2 M1 | Round 3 M2 | Round 1 M2 | Round 2 Submit your complete application by ... 13 Dec 20 Feb 28 Apr 31 Mar 28 Apr You will be notified of the outcome of your application by ... 25 Jan 15 Mar 23 May 25 Apr 23 May Accept your place by ... 8 Feb 29 Mar 6 Jun 9 May 6 Jun Pay your first tuition installment by .... to qualify for a reduction in tuition fees (international non-European students) 25 Feb * 15 Apr ** N/A 25 May *** N/A Pay your first tuition installment by .... with no reduction in tuition fees 25 Mar 15 May 15 Jun 15 Jun 15 Jun

Early Bird Applications 2024-25- * A reduction of €1,500 for the M1 study year is granted to non European international students who apply during the first admissions round and make their first tuition payment within one month of being offered a place on the programme.

- ** A reduction of €500 for the M1 study year is granted to non European international students who apply during the second admissions round and make their first tuition payment within one month of being offered a place on the programme.

- *** A reduction of €1,500 for the M2 study year is granted to non European international students who apply during the first admissions round and make their first tuition payment within one month of being offered a place on the programme.

- Admission requirements

-

Admission requirements for the first year (M1)

- International students with a bachelor's degree (Bachelor of Engineering, Bachelor of Science, Bachelor of Technology) or equivalent, in a field related to Science and Technology

- French and European students with a 'license' qualification or equivalent.

- Students must have graduated from the above before the end of August in order to enrol in a Master's Programme at Centrale Nantes in September.

- Applicants must have a good level in Mathematics and be fluent in English - written and spoken. An applicant whose native language is not English is required to submit a certificate, which is no older than three years, for a recognised international test of English*:

- TOEFL - IBT 80, or ITP 550, paper-delivered test 60, TOEFL Home edition is accepted,

- Cambridge B2 First Test - 173 or higher,

- Cambridge C1 Advanced Test - 160 or higher,

- IELTS - 6.5 or higher, IELTS Online test is accepted

- TOEIC - 800 or higher.

- Applicants who carried out their studies in English (you must provide an official confirmation letter from your university) are eligible without passing such a test, but providing the results of a recognized international test can add value to the application.

- Students who completed their studies in the countries listed below are exempted from submitting a language certificate: Antigua and Barbuda, Australia, The Bahamas, Barbados, Belize, English-speaking Canada, Gambia, Ghana, Grenada, Guyana, Republic of Ireland, Jamaica, Kiribati, Liberia, Mauritius, Micronesia, New Zealand, Nigeria, Papua New Guinea, St. Kitts-Nevis, St. Lucia, St. Vincent, Sierra Leone, Solomon Islands, Trinidad and Tobago, United Kingdom, United States of America, Zambia or Zimbabwe.

*no other test is recognised.

Language of instruction

Fully taught in English.

Students who have successfully completed a first year MSc programme can apply for the second year MSc programme.

Admission requirements for the second year (M2)Language of instruction

Fully taught in English. - Required documents

-

When applying for a Centrale Nantes MSc Programme you will be asked to provide the following documents:

- Your official transcripts

- A CV/Resume and cover letter

- Your diploma

- Proof of English proficiency

- Two letters of recommendation

- Your passport or other form of official identification

Your documents must be uploaded in English or French. If the original version of your documents is not in one of these two languages, a certified translation by a sworn translator is required.

- Apply online

-

Apply online on the eCandidat platform

How to use the eCandidat platform:

- Download the user guide

- Connect to eCandidat: https://ecandidat.ec-nantes.fr

- Use the flag (page top right) to select your language.

- Start off by creating your account.

- No application fees.

Contact and admissions support

Master Admission Office

master.admission@ec-nantes.fr

Tel: +33.2.40.37.68.36 / 33.2.40.37.68.51

Chinese students: lichunlai@ec-nantes.cn

Indian students: application@galaxy-edu.com - Tuition fees and financing

-

Tuition Fees

International students (non-European)

M1 Year €10,000 * M2 Year | 2024 - 2025 €6,000 - (students starting their M2 year in 2024) ** M2 Year | 2025 - 2026 €8,000 - (students starting their M2 year in 2025) **

Early Bird Applications- * A reduction of €1,500 for the M1 study year is granted to non European international students who apply during the first admissions round and make their first tuition payment within one month of being offered a place on the programme.

- * A reduction of €500 for the M1 study year is granted to non European international students who apply during the second admissions round and make their first tuition payment within one month of being offered a place on the programme.

- ** A reduction of €1,500 for the M2 study year is granted to non European international students who apply during the first admissions round and make their first tuition payment within one month of being offered a place on the programme.

European students

€243 per year

Financing your studies

Different scholarships are available for students enrolling in a MSc Programme at Centrale Nantes:

Scholarships

- Centrale Nantes Elite Scholarship

- Government scholarships

- Inter-government scholarships

- Industry scholarships

- Scholarships from organisations

- European Programmes

Other ways to help you finance your way through your studies:

- Paid 6-month internship

You will be paid for your 6-month Master's thesis / internship in France. For internships undertaken in France that exceed two months in duration a minimum level of remuneration is set by the government, at approximately €600 per month. In some professional branches, this amount may be higher. - Work alongside your studies

You are entitled to work part-time alongside your studies, to earn some extra money. This option is available for both European and non-European students, but different rules apply. Learn more - Help with your rent

French and international students are eligible to receive financial support (known as APL in French) from the CAF (Caisses d'Allocations Familiales). The CAF is a French government organism that covers part of the monthly cost of rent paid for student accommodation – the allocated amount depends on the type of accommodation and on your income. Learn more (in French)

Meet our Mechanical Engineering Students

- Why choose this MSc?

-

- After the MSc

-

Career Prospects

- Sectors: Aeronautics, Automotive, Transportation, Wind and Marine Energy, Mechanics, Consulting

- Fields: Mechanical Engineering, Design, Materials, Advanced Processes, Additive Manufacturing, Research and Innovation

- Positions: Mechanical Engineer, Process Engineer, Design Engineer, Research and Innovation Engineer (post PhD)

Where are they now?

► Find out what our recent MSc graduates are doing now - What our students / graduates say

-

Read what our students / graduates have to say about the programme: coming soon

- Meet the Programme Supervisors

-

Matthieu Rauch, M2 Programme Supervisor AM

Christian Burtin, M1 Programme Supervisor Mechanical Engineering

Patrick Rozycki, Programme Supervisor Mechanical Engineering

Patrick Rozycki is a professor in Rigid Bodies Dynamics, Crash and Impact and Composite Materials at Centrale Nantes. His research mainly involves identifying and modelling composite behaviour from quasi-static to dynamic loading, including environmental effects (temperature and air conditions).

He is the Assistant Dean of Studies for Master Programmes and Programme Supervisor for the Master of Science programmes in Mechanical Engineering - Campus facilities

-

Centrale Nantes houses 17 buildings on a 40-acre green campus. In addition to the standard facilities of a university campus (classrooms, media library, computer rooms, etc.), it is home to 13 research platforms, some of which are unique in France, and modern and varied sports facilities, the Centrale-Audencia-Ensa incubator and vibrant student life. Facilities on the Centrale Nantes campus:

- 45 classrooms

- 6 lecture theatres

- 13 computer rooms (with nearly 180 fully equipped PCs and extended opening hours)

- 1 media library

- 5 research institutes

- Sports and cultural facilities: 1 gymnasium, 1 multisport/dojo hall, squash courts, 1 piano room

- 1 student house

- Student halls of residence and accommodation support

- 1 online platform for students, Onboard, with timetables, grades, attendance management, distance learning and teaching resources,

- 1 Moodle platform (Hippocampus) with collaborative functionality available to faculty and students (additional resources, working groups, forum, online assessments, etc.).

- Students also have access to meeting rooms / learning innovation / videoboxes equipped with video projectors, cameras, interactive whiteboards, etc., for their classes, presentation preparation, project work, etc.

- 1 lifelong email address and an individual digital workspace and storage space, with remote 24H access.

Explore the campus with its classrooms, research platforms, student life and sports activities: Take the virtual tour

Virtual Tour

Programme Supervisor

Matthieu Rauch (Matthieu.Rauche79839d5-9e08-440b-b805-4685fa8d5b67@ec-nantes.fr)

Admissions Contact

Apply online

- 2024/25 intake: M1 applications open on 30 Oct 2023

- 2024/25 intake: M2 applications open on 15 Feb 2024

- Apply here

Meet us

Meet us

We regularly attend education fairs around the world to meet with prospective students and provide information about our study programmes.

► Stay tuned for upcoming events

Download the flyer

Download the flyer

Study

- UNDERGRADUATE

- GRADUATE

- Engineering Programme "diplôme d'ingénieur"

- Fast-track Engineering Programme

- 5 Master of Science (MSc) Programmes with 10 Specialisms

- Integrated Master-PhD Track

- 5 Erasmus Mundus Joint Masters

- 3 Joint Master's Programmes

- Advanced Master's "Mastère Spécialisé ® "

- Degree apprenticeship in partnership with ITII

- PhD

- EXCHANGE STUDENTS

- EXECUTIVE EDUCATION

- TUITION FEES AND FINANCING

- MEET OUR GRADUATES

- APPLY NOW

- INNOVATIVE TEACHING

- A VOCATIONAL APPROACH

- ENTREPRENEURSHIP

- CIVIC ENGAGEMENT

- DEGREE CERTIFICATES

- KEY DATES FOR THE ACADEMIC YEAR