Our research impact: industry of the future

The 'industry of the future' is emerging as a technological and organisational revolution, redefining the way companies produce, interact and evolve, enabling rapid adaptation to changing market demands. Manufacturing flexibility and the circular economy are gaining in importance, promoting sustainable production. This technological revolution promises not only increased efficiency, but also a profound transformation of contemporary economic and environmental models.

At Centrale Nantes, these developments are at the heart of many of our research projects.

At Centrale Nantes, these developments are at the heart of many of our research projects.

Flagship projects

Additive4rail

SNCF, Centrale Nantes, VLM Robotics and 4DPioneers launched the Additive4Rail consortium with state support. The aim is to speed up the industrialisation of additive manufacturing technologies in order to streamline train maintenance and reduce costs by producing components piecemeal or in small batch runs.

Read on to discover some of the different ways Centrale Nantes research is contributing to meeting the challenges of tomorrow's industry.

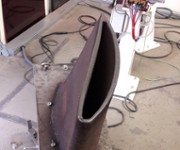

- Naval Group and Centrale Nantes print the world’s first hollow propeller bladeFebruary 28, 2024Naval Group and Centrale Nantes have printed the first demonstrator of hollow propeller blades by metal additive manufacturing as part of the European H2020 project, RAMSSES*.

- AMOS: Additive Manufacturing Optimisation and Simulation ProjectFebruary 28, 2024Centrale Nantes is one of the partners in the ongoing Additive Manufacturing Optimisation and Simulation (AMOS) project, which is developing a number of additive materials and processes for the repair of aircraft parts. The four-year AMOS project benefits from European funding under the Horizon 2020 programme, as well as Canadian funding through the agencies CARIC and NSERC.

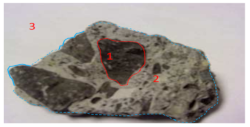

- New concrete based on co-products to reduce greenhouse gas emissionsFebruary 28, 2024The Research Institute in Civil and Mechanical Engineering (GeM, UMR 6183) at Centrale Nantes is currently working on the ECOREB project which aims to define concrete formulations made of aggregates resulting from the demolition of concrete structures that can be used in the design of infrastructure and buildings.